Laser cleaning application

Common metal and steel surface treatment technology levels are polishing, sandblasting, wire drawing, anodizing,electrophorelsis, PVD, electroplating, etching, spraying, and laser;it matches the material of the work object(Metal, stainless steel, iron, galvanized aluminum...) and other methods, the so-called surface treatment, the contact surface should be smooth, smooth, and even the same color.

The above-mentioned surface treatment methods use related tools, machinery, chemical agents, soaking or smearing, repeated cleaning and wiping, etc., which are not friendly to the environment. Users also have certain safety concerns when processing metals and steel, and consume a lot of money.Finished materials.

HOUR laser rust removal cleaning machine has a wide range of applications.

Its laser cleaning characteristics can not only increase the durability of use, and extend the durability of the used items. It can effectively clean the surface of oily dirt, stains, and dirt; the cost of consumables can be effectively reduced.

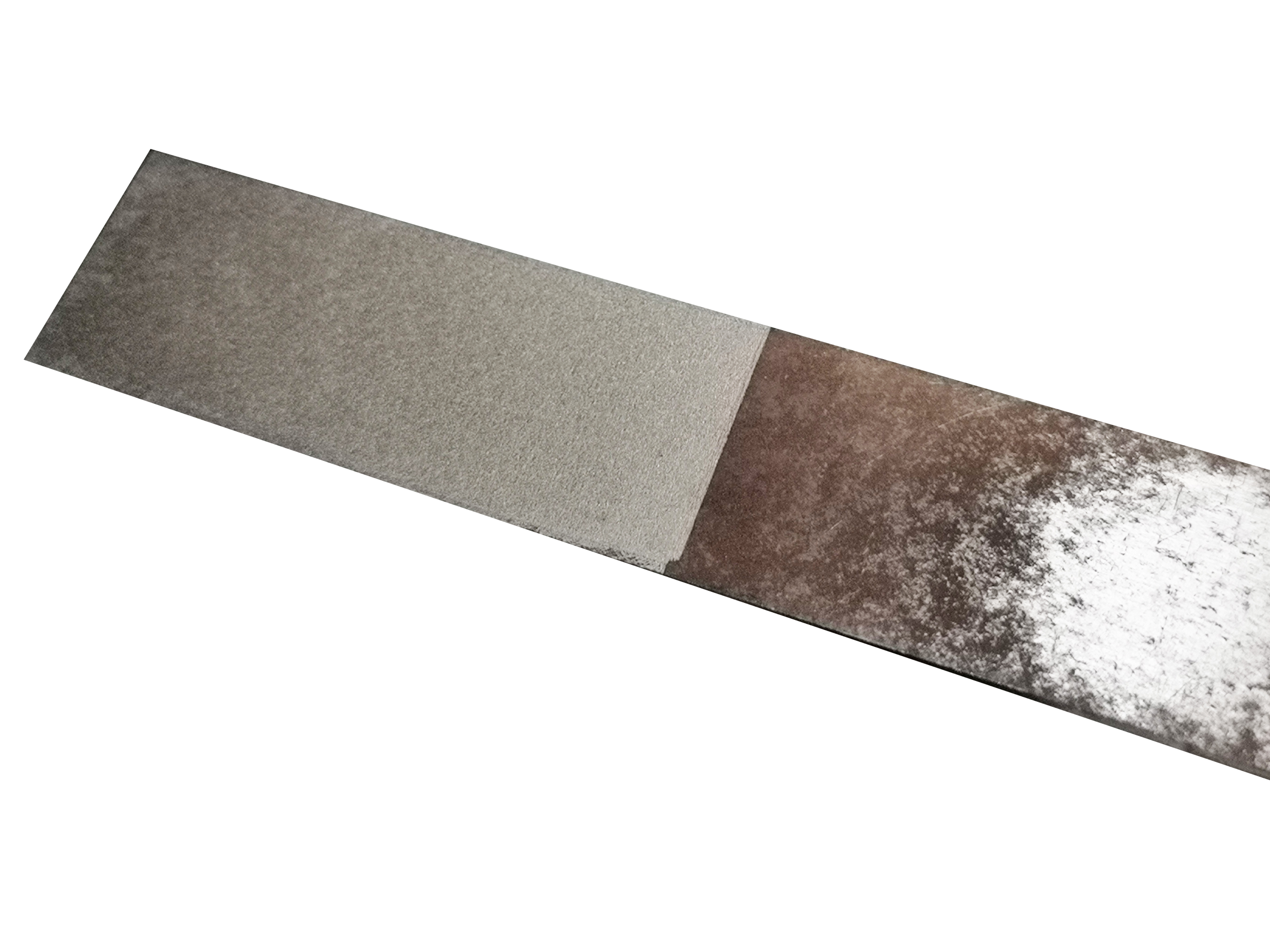

Metal surface rust removal

The metal surface rust layer treatment can be cleaned and removed by a laser rust remover without damaging the surface of the part. It does not contain chemicals, is safe and environmentally friendly, has high efficiency and simple operation.

Paint stripping treatment

Metal surface paint and paint remover use paint remover and paint remover, which has a strong ability to dissolve the paint film. However,because some paint removers are corrosive, the Hower laser rust remover has no chemical cleaning problems and is safe.Quickly remove paint.

Weld bead cleaning treatment

The handheld laser derusting machine effectively solves the hidden dangers of the traditional welding bead cleaning site chemical consumables cost and the use of chemicals. The laser derusting machine is simple to operate, and the laser weld bead cleaning process is fast and safe.

Oxidation treatment

Metal surface rust layer treatment can be achieved by using a laser rust

remover to clean and remove the rust layer without damaging the surface of the parts. It is chemical-free, safe and environmentally friendly, has high efficiency and is easy to operate.

Mold surface treatment

Paint stripping and paint stripping treatments on metal surfaces all use paint stripping and paint stripping agents that have a strong ability to dissolve paint films and are highly efficient. However, because some paint strippers are corrosive, Haoer laser rust removal and cleaning machine does not require chemical cleaning. Problem, safety, quick paint removal.

Oil stain treatment

Metal surface rust layer treatment can be achieved by using a laser rust remover to clean and remove the rust layer without damaging the surface of the parts. It is chemical-free, safe and environmentally friendly, has high efficiency and is easy to operate.

| HOUR LASER

|

Contact Us

- TEL: +886-7-269-6509

FAX: +886-7-213-4646

E-MAIL:hour.cares@gmail.com

No.85-1, Ln. 181, Huiying St., Daliao Dist., Kaohsiung City 831137, Taiwan (R.O.C.)